HEAVY DUTY ENGINES

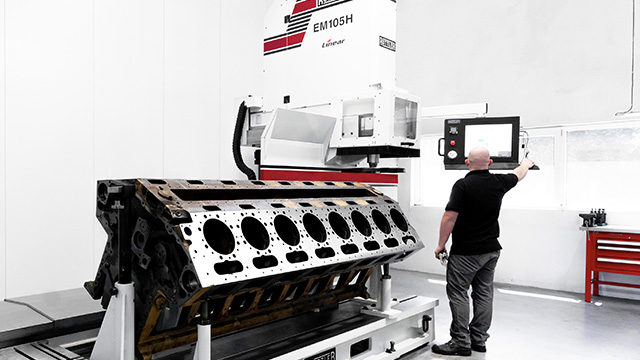

DZIAK Heavy Duty Engines service was established to provide professional service to customers remanufacturing engines with capacities between 13,000 and 120,000 cc. Newly acquired, CNC-controlled machine tools dedicated to machining this type of engine parts enable the regeneration process to be carried out professionally.

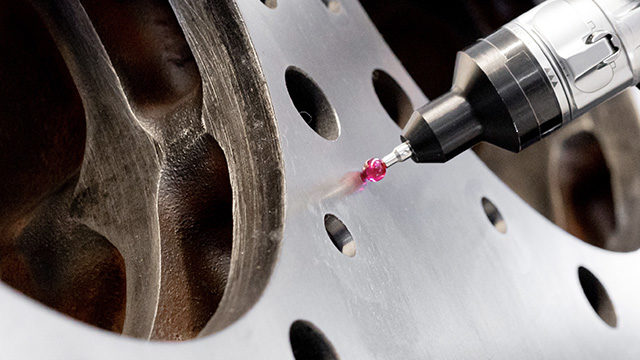

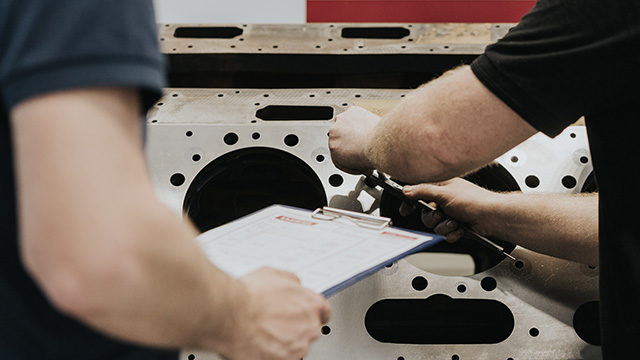

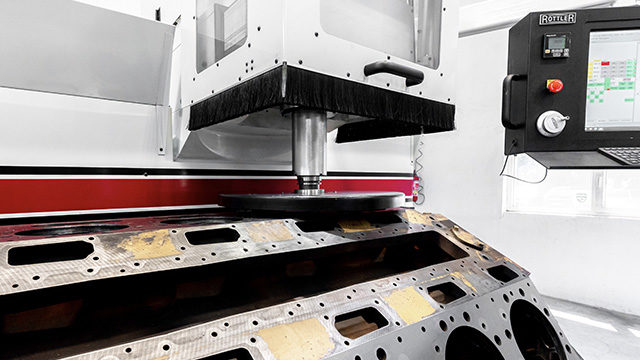

Combined with our qualified and experienced staff, we ensure the highest quality of the services we provide. As the only one in Poland, we own the Rottler EM105H machine. This machine provides precision in machining all planes, holes, threads, etc. with position repeatability down to 0.005 mm. It is a dedicated milling machine for machining blocks of large engines up to V20 size, such as CAT3520 and C175 V20, MTU 4000 V20, Cummins QSK78, Waukesha 9390. The largest block length we can regenerate on it is approximately 3,500 mm. This machine ensures maximum precision in machining all planes, holes, threads, etc. Confirmation of the highest accuracy of the repairs, such as the alignment of the main pan supports or the flatness of the surfaces, is obtained by checking with the Easy Laser measuring system. Our machinery is constantly being expanded and improved. We also have an AMC-Schou K-4000 crankshaft grinder that can be used to grind crankshafts up to 4200 mm long.

RANGE OF SERVICES

- Regeneration of blocks

- Regeneration of connecting rods

- Regeneration of cylinder heads

- Regeneration of crankshaft

- Milling work on CNC machines for workpieces up to 4000 mm long

- Cylinder block main bearing caps alignment measurements with Easy Laser

- Measuring and scanning with the Hexagon Absolute Arm 85

- Dynamic balancing of crankshafts